Understanding Your Miller Welding Chart: A Step-by-Step Approach

The Miller welding chart isn't a complex formula; it's a straightforward guide to selecting the correct welding settings. Mastering it significantly improves your welding skills, saving you time and frustration. Let's break down the process step-by-step:

Identify Your Metal: Locate the section corresponding to your metal type (e.g., steel, aluminum, stainless steel). Accuracy here is crucial for a successful weld.

Measure the Thickness: Precisely measure your metal's thickness. The chart provides different settings for varying thicknesses. Minor inaccuracies can result in weak or faulty welds. Always double-check your measurements.

Choose Your Welding Method: Select the correct section for your welding process—MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), or stick welding (Shielded Metal Arc Welding). Using the wrong section leads to incorrect settings and potential hazards.

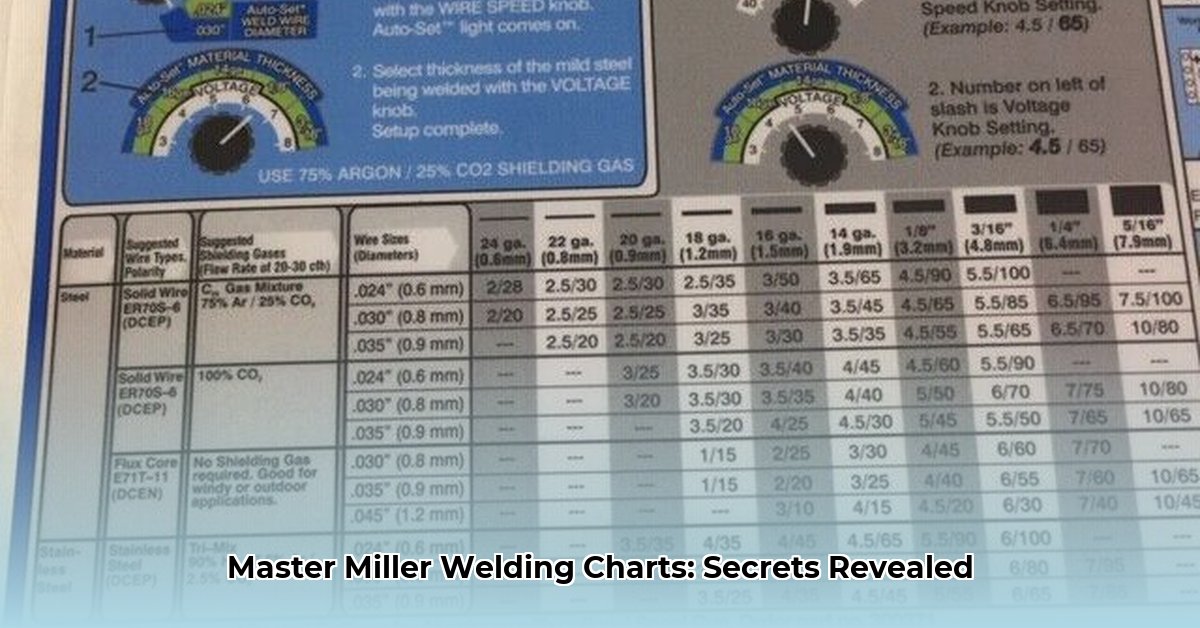

Find Your Perfect Settings: Locate the intersection on the chart where your metal type, thickness, and chosen welding process converge. This pinpoint provides the recommended amperage (electrical current), voltage, wire speed (for MIG), and gas flow rate. This is your starting point.

Fine-Tune Your Settings: The chart offers initial guidelines; minor adjustments might be needed based on factors such as ambient temperature and weld position. Observe the weld's appearance—the visual quality is a great indicator for necessary tweaks. Experience plays a vital role here.

Practice, Practice, Practice: Consistent use is key to mastering the Miller welding chart. Experiment within safe boundaries; each weld provides learning opportunities. Over time, you'll develop intuition for optimal setting adjustments.

Did you know that 80% of welding defects are caused by improper settings? Using the chart correctly drastically reduces this risk.

Exploring the Sections of Your Miller Welding Chart

While specific details vary slightly between Miller welding charts, these core sections are common:

Material Properties Section: Describes the characteristics of different metals (melting points, tensile strength, etc.), aiding in setting selection.

Welding Process Parameters Section: Provides detailed instructions and settings for MIG, TIG, and stick welding, outlining recommended voltage, amperage, wire feed speed, and gas flow.

Weld Types and Configurations Section: Offers information and parameters for various weld types (fillet welds, butt welds, lap welds). Different welds require different settings for optimal strength and appearance.

Troubleshooting Guide (Often Included): Many charts include a troubleshooting section to help diagnose and resolve common welding problems, offering potential causes and solutions for weld defects.

Avoiding Common Welding Pitfalls

Even experienced welders encounter issues. Here are frequent problems to avoid:

Incorrect Material Selection: Using the wrong material section on the chart can lead to significant weld defects. Always double-check your metal identification.

Inaccurate Thickness Measurement: A slight error in thickness measurement can result in insufficient penetration (weak weld) or excessive burn-through (hole in the metal). Precision is key.

Neglecting Shielding Gas: For MIG and TIG welding, ensuring adequate gas flow is critical to prevent weld defects. Check for any gas leaks.

Beyond the Chart: Elevating Your Welding Skills

Consult Your Equipment Manual: Use the Miller welding chart in conjunction with your welding machine's instruction manual for complete guidance.

Prioritize Safety: Welding involves inherent risks; utilize appropriate safety gear including a welding helmet, gloves, and protective clothing.

Maintain Your Equipment: Regular cleaning and maintenance improve the consistency and longevity of your welds.

Mastering the Miller welding chart is an ongoing process that significantly improves your welding prowess. It offers a strong foundation, but practice and attention to detail ensure consistent, high-quality results. Now, go forth and create beautiful welds!